Challenge

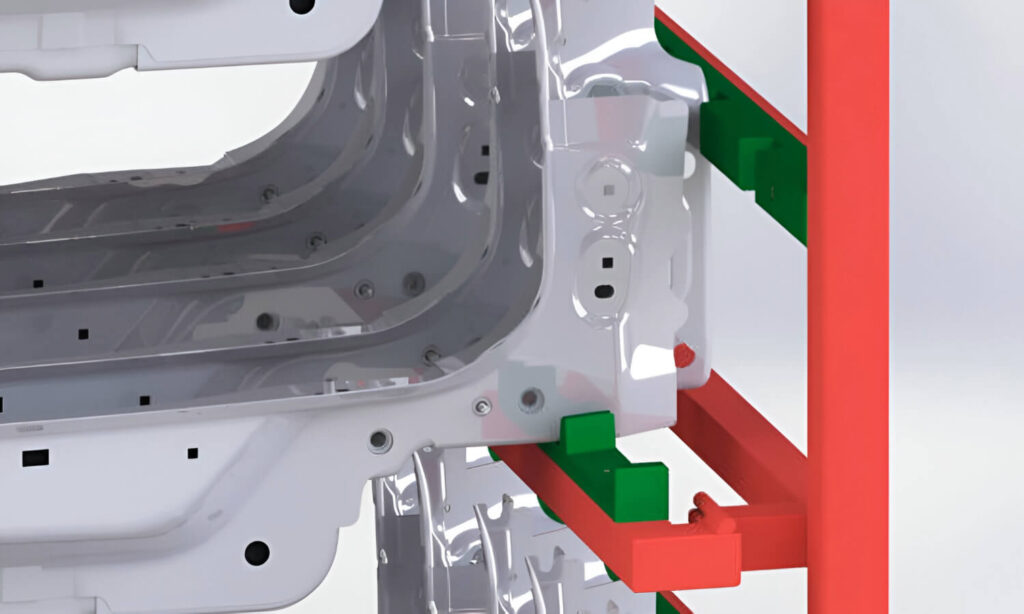

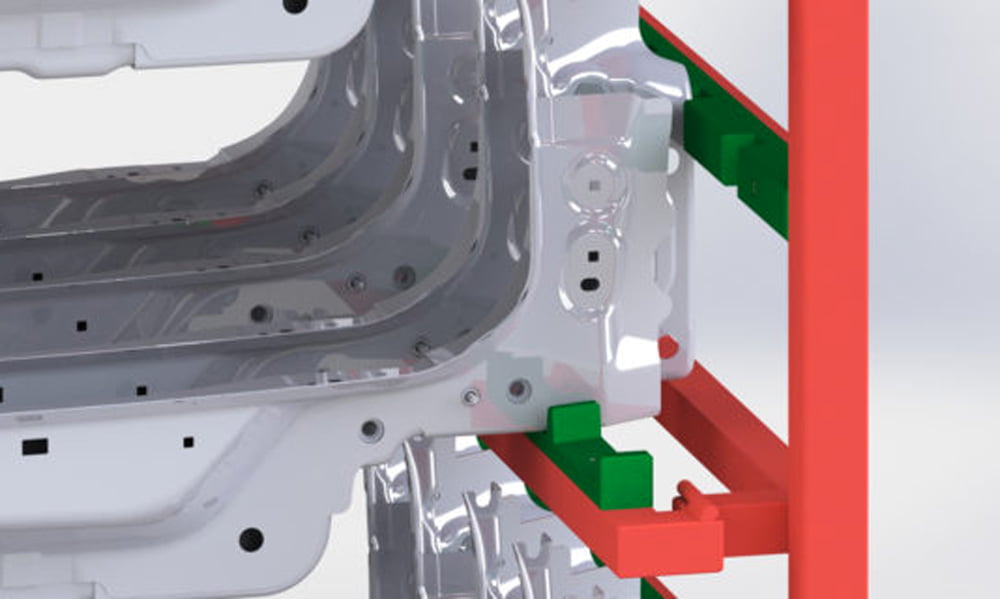

Kuka Systems, a German manufacturer of industrial robots and systems for factory automation, required the design and manufacture of storage stillages to work in body in white (BIW) production for JLR, to transport automotive panels between manufacturing cells. The stillage needed to be robust to last the lifecycle of the car, ergonomic to use and quick to load and unload.

Solution

Utilising our industrial design service, initially all of the clients 3D CAD data was collated to ensure relevant panels were accommodated for. The industrial design team then utilised their knowledge and experience of panel holding to design suitable nylon and polyurethane dunnage to support the panels. Concepts and prototypes for each stillage required were then presented to the client for approval.

Result

The final solution was robust, versatile, easy to use and integrated with factory automation systems. Following approval 200 stillages were manufactured for the line in total, and subsequently further stillages were designed for a new model.

Team Feedback

We don’t limit ourselves to metalwork. Our industrial design team is experienced in producing designs that also incorporate non-sheet metal components.

Project Manager

Services & Solutions from this project

Design to delivery, adding value at every stage

Discover how we partner with businesses to add value and bring products to life.