Our story so far

From humble beginnings and two employees, to over 54,900 square feet of manufacturing space.

Take a look back at the company history and its key milestones to discover how we’ve grown, building upon our success to offer a truly end-to-end sheet metal manufacturing service.

2024

JANUARY

New leadership team formed

New leadership team established with the promotions of three individuals to Director level. Andy Tuck becomes Sales Director, Jarek Gasiorek Production Director, and Matt Grealy Technical Director. They join Managing Director Tom James and Chief Executive Jason Austin to form the new leadership team at Unifabs Ltd.

2023

AUGUST

Equipment investment: Haeger Insertion systems

Two Haeger 824 WindowTouch 5e Fastener Insertion systems installed to boost efficiency and productivity in sheet metal services.

JULY

Investment in green energy

£355k investment made to switch to solar energy, helping to reduce carbon footprint. 955 PV modules installed across approx 2000 m² roof space.

JULY

Equipment investment: Salvagnini P2 installed

Investment in a second Salvagnini P2 delivers increased capacity for automated panel bending.

JUNE

Equipment investment: Fanuc Robot Welding system installed

A six-axis Fanuc AM100id (R30ib mate controller), with a Kemppi 350A A7 MIG welder and Binzel torch system installed to increase robotic welding capacity.

MAY

2022

SEPTEMBER

Celebrating 15 years

Unifabs celebrates 15 year anniversary

AUGUST

Unifabs Academy launched

Proud to be supporting the next generation, summer 2022 saw Unifabs launch its very own academy for manufacturing and engineering apprentices in partnership with Train’d Up.

2021

DECEMBER

Gains Living Wage Accreditation

Unifabs proud to become an accredited Living wage employer.

DECEMBER

Management team restructure

Tom James promoted to Managing Director and Jason Austin becomes Chief Executive.

DECEMBER

Equipment investment: Amada HRB ATC

Unifabs adds new press brake with automatic tool change to metal bending capabilities to increase efficiency and support prototyping.

NOVEMBER

Equipment investment: Amada REGIUS Laser profiling centre

Unifabs becomes one of the first companies in the UK to receive the ground breaking REGIUS-3015AJ laser cutting machine from Amada, increasing cutting capacity and bringing a multitude of benefits to our customers.

MAY

Equipment investment: Salvagnini P2 Lean installed

Unifabs adds significant capability in panel bending with the addition of a Salvagnini P2lean for automated panel bending, unlocking potential design and commercial improvements for our customers.

2020

DECEMBER

Turnover reaches £10 million

Unifabs successfully grows business, doubling turnover in just 4 years to £10M

OCTOBER

Acquired additional manufacturing space, £1.4 million investment in plant

Four more units purchased increases manufacturing space by 23,000 sq. ft., to total 52,000 sq. ft. and allows for dedicated area for drilling, sawing and tapping.

2019

DECEMBER

Equipment Investment: Fanuc Robotic Welding System installed

State-of-the-art robotic welding system installed delivering capability to produce more consistent, repeatable welds on manufactured products.

JUNE

New unit acquired

Unifabs expanded its facilities providing a dedicated fabrication centre for welding. Increasing manufacturing space to 29,000 sq. ft. In 2021 the space was repurposed into our Forming Centre.

APRIL

Celebrating 100 Employees

Unifabs proud to reach 100 employees

FEBRUARY

2018

NOVEMBER

Coventry Telegraph Business Awards Winner

Unifabs celebrates two big wins at the Coventry Telegraph Business Awards. Chief Executive, Jason Austin wins ‘Entrepreneur of the Year’ and Unifabs Ltd wins ‘Excellence in Industry’ awards.

2017

DECEMBER

Purchased additional space

Added 20,000 sq. ft. of additional space acquired on Haunchwood Park Drive, currently the Finishing Centre

2016

DECEMBER

Turnover reaches £5 million

Unifabs celebrates business growth to £5M turnover

SEPTEMBER

10 Years of Unifabs

Unifabs celebrates 10 years in business

2014

DECEMBER

Acquired additional manufacturing space

Currently the Welding Centre

2013

Acquired additional manufacturing space

Currently used for Design, R&D, and the Academy

2011

SEPTEMBER

Became ISO9001 accredited

ISO 9001 is the world’s most recognised quality management system standard, it helps organisations implement clear, repeatable processes to maintain a quality service for their customers.

AUGUST

Moved to new premises

Moved to sheet metal factory on Haunchwood Park Drive

Industrial Design Services now offered

Industrial Design is added to our portfolio of manufacturing services allowing us to support our customers from initial concept, and adding value through manufacturing design solutions.

OCTOBER

Change of ownership

Jason Austin, one of two founding members, acquired sole ownership of the company

2007

SEPTEMBER

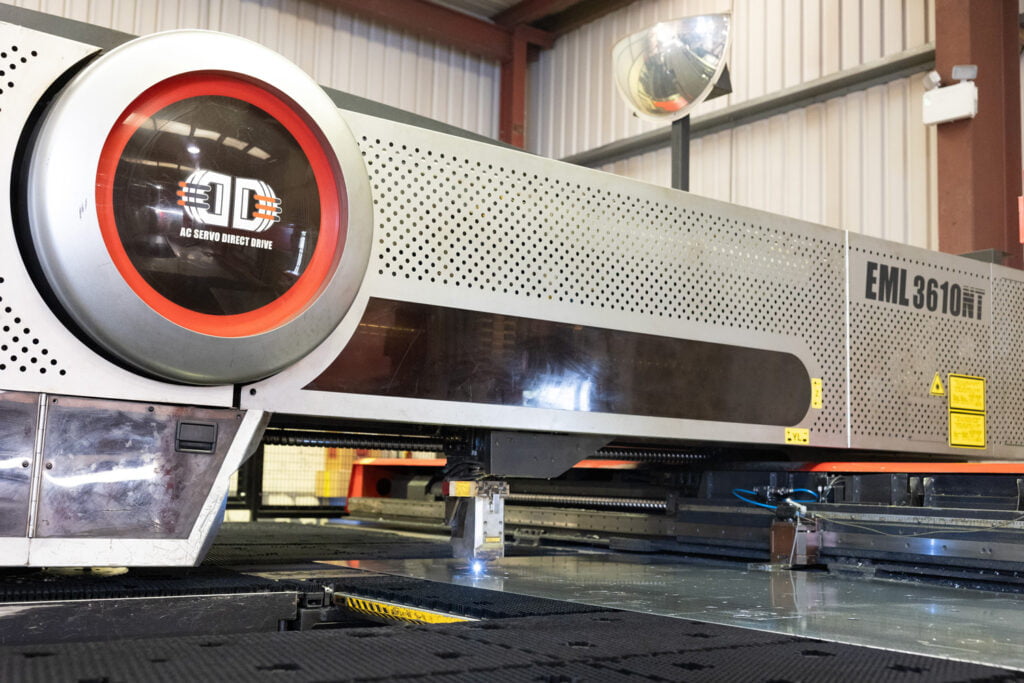

Equipment investment: First machine purchased Punch/laser combination

Unifabs purchased its first machine, an Amada EML punch/laser combination. This was located in rented factory space.

Unifabs Ltd founded

Unifabs Ltd is established delivering quality sheet metal fabrications.

Join us

If you think you have what it takes to join our expert team of

DESIGNERS / ENGINEERS / FABRICATORS

We’d love to hear from you.