Manufacturing expertise at every stage

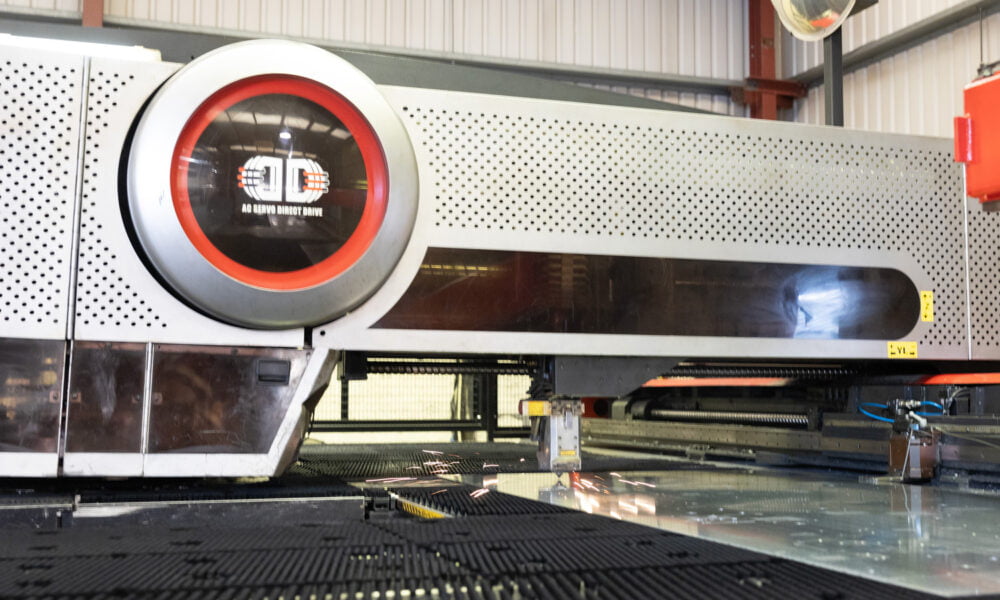

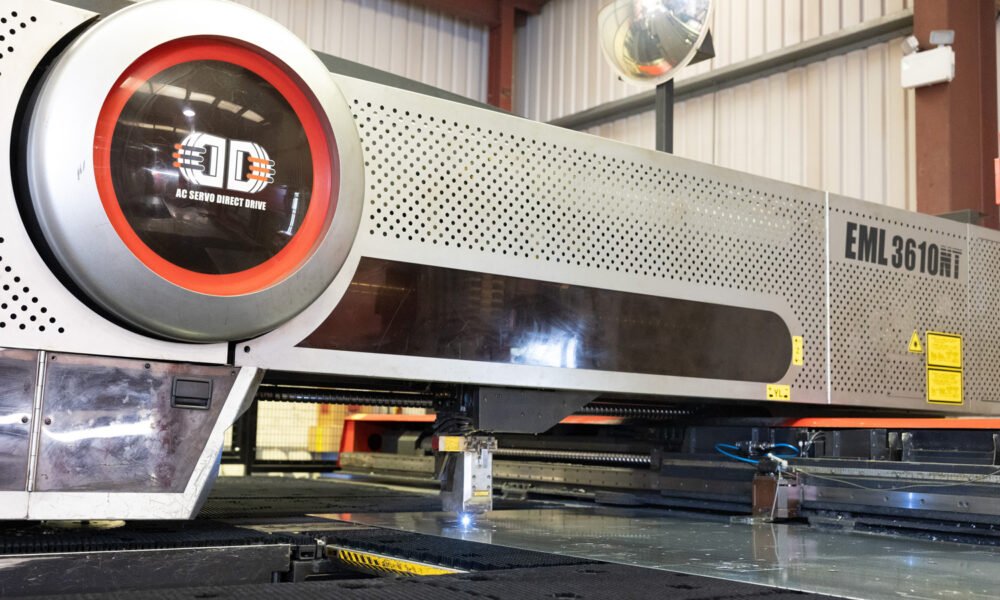

With extensive experience in sheet metal manufacture, our team of experts utilise the most appropriate and cost-effective methods for each product. The punch laser CNC machine at Unifabs combines the best features of a punch, with the flexibility of a laser to deliver the ultimate in performance.

Taking the strongest features from each machine we are able to punch, form, tap and laser cut on one machine, eliminating secondary operations and thus the requirement to program twice for one part.

One machine, two technologies, first-class efficiency

A part with an intricate outside profile combined with raised punch forms within it can easily be produced on the punch laser CNC machine. First, it punches the internal forms, then switches the multi-tool turret to the laser head to create the outside profile.

This switch from punch to laser technology can be applied across a full nest of parts. To further maximize efficiency, the laser punch combination machine is coupled with automated load/offload cells, allowing lights-out manufacturing.

Advantages of a punch laser CNC machine

This combination of technologies delivers an array of benefits. It reduces operator requirements since one CNC machine performs the processes instead of two.

It also reduces production times because parts don’t need to be transferred to secondary processes. Utilising a laser can eliminate the need for complex or custom punch tooling thus reducing costs.

All of these advantages translate to high-quality, lower-cost parts delivered to you faster.

Materials

- Mild Steel

- Stainless Steel

- Aluminium

- Pre-Galv

- Zintec

- Copper

Capabilities

Sheet size

3000 x 1500mm

Material thickness

Laser up to 6mm

Punch up to 3mm

Technology

- Amada Punch Laser Combination (EML3610NT 4KW) with MP 6T loading system with tapping head

- Amada Togu III Auto Tool grinding

Our Punch Laser CNC Machine Combination Capabilities

Our CNC punch laser combines the best features of a punch with the flexibility of a laser.

Amada Punch Laser Combination

(EML3610NT 4KW) with MP 6T loading system with tapping head

Incorporating the latest advances in punching and laser cutting technology, the EML NT combines Amada’s revolutionary EM (Electric Motor) punching technology with the reliability of Amada’s hybrid laser motion system. The result is one of the most productive CNC machines on the market delivering unequalled precision and flexibility.

Amada Togu III Auto Tool Grinding

We understand the importance of tool maintenance to ensure the finest quality punched parts. The Amada Togu is the perfect accompaniment to our CNC punching machines. The automatic tool sharpener purposely designed for high quality sharpening of sheet metal tools keeps them in optimal condition, maximises tool life and ensures quality punched holes.

Everything you need to know about Punch Laser Combination machine

Here is an overview of questions that we are most commonly asked.

Want to learn more?

Answer

Answer

Answer