Maximising efficiency and quality in laser cutting

We are equipped with high-speed fibre laser cutting machines that excel at medium to high volume runs, helping to manufacture your products more quickly and efficiently.

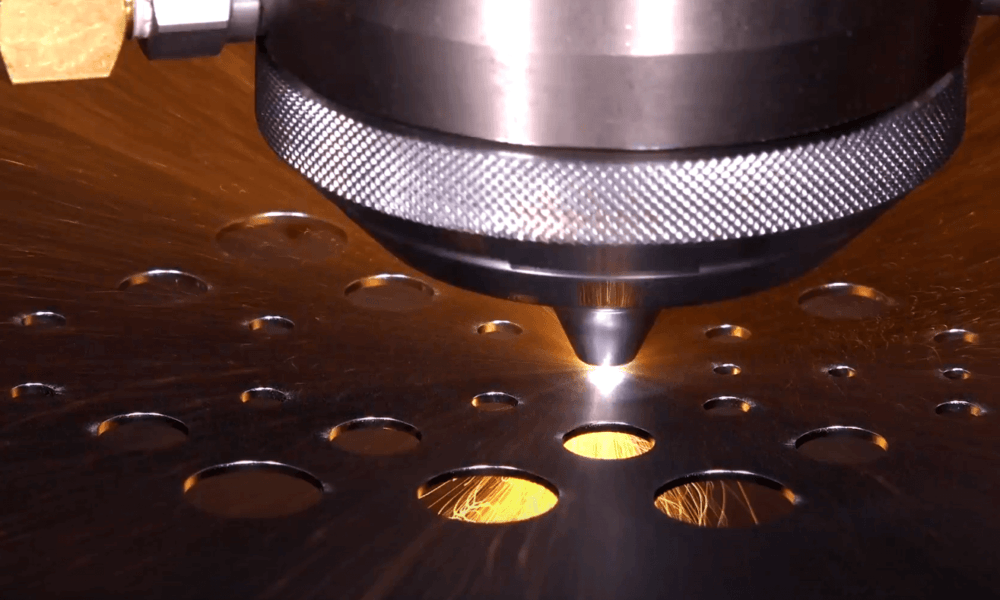

How does laser cutting work?

Laser cutting is a thermal process whereby a high-power-laser beam is directed at a material in order to melt, burn or vaporise the area away. The laser is programmed to follow a CAD file in order to produce the required design.

From small and simple, to larger and more intricate designs, one laser can be used for an array of applications by utilising beam control technology to allow the beam to cut in the most optimal way for the material and the application.

Staying at the forefront of sheet metal manufacturing

The machines at Unifabs use fibre optic delivery systems which produce a much purer beam and use less power than traditional CO2 machines. The laser head on our machines travels on a linear drive system, making them even faster and more accurate than traditional, mechanical technologies.

Part of Unifabs growth strategy is to continually invest in the latest technology and manufacturing techniques. This ensures that we remain at the forefront of the sheet metal manufacturing industry and supports our mission to become a trusted contract manufacturing partner to our customers.

Our latest investment in fibre laser cutting is the Amada REGIUS AJ, and we were one of the first in the UK to receive the ground-breaking machine. This enabled us to increase capacity and offer our customers unparalleled levels of quality in high-speed precision metal laser cutting.

Materials

- Mild Steel

- Stainless Steel

- Aluminium

- Pre-Galv

- Zintec

- Brass

- Copper

Capabilities

Sheet size

3000 x 1500mm

Material thickness

up to and including 20mm

Technology

- Amada REGIUS-3015AJ Fibre Laser Profiling Centre with AS LUL-3015 loading system

- Amada FOL-AJ 4KW Fibre Laser with AS LUL loading system

- Amada Punch Laser Combination (EML3610NT 4KW) with MP 6T loading system with tapping head

Our CNC Laser Cutting Capabilities

Our CNC Laser cutting machines deliver the very best in high speed precision laser profiling.

Amada REGIUS-3015AJ

Fibre Laser Profiling Centre with AS LUL-3015 loading system

Offering high quality, unrivalled cutting performance, the REGIUS profiling centre delivers next level processing with its 3-axis linear drive and Amada’s original Variable Beam Control technology. This extremely high-speed and accurate technology, coupled with a load/offload system, maximises machine up-time and ensures an uninterrupted production run.

Amada FOL-AJ

4KW Fibre Laser with AS LUL loading system

The Amada FOL-AJ delivers high quality laser cutting at speed all from a compact footprint. Its short wavelength fibre laser beam also provides an expanded process range for materials including copper and brass with added benefits of low energy consumption.

Amada Punch Laser Combination

(EML3610NT 4KW) with MP 6T loading system with tapping head

Incorporating the latest advances in punching and laser cutting technology, the EML NT combines Amada’s revolutionary EM (Electric Motor) punching technology with the reliability of Amada’s hybrid laser motion system. The result is one of the most productive fabricating machines on the market delivering unequalled precision and flexibility for our customers.

Driving productivity through automation

Our laser cutting machines are supported by 15T automated sheet load/offload cells. This ensures uninterrupted production runs and optimises the laser cutting machinery’s utilisation. Making our setup truly designed to maximise output and efficiency.

Ultimate versatility

Our team of experts have extensive knowledge and expertise in sheet metal manufacture across a broad range of materials and an array of manufacturing methods at our disposal.

We utilise the most appropriate, cost-effective and efficient method of manufacture for each product. With the punch/laser combination at Unifabs we are able to deliver unmatched performance, punching, forming, tapping and laser cutting on one machine to eliminate the need for secondary operations, reducing the cost to our customer.

Manufacturing expertise at every stage, wherever you are

Although we do offer laser cutting as a stand alone service, laser cutting is often the starting point for many jobs utilising our full range of manufacturing services.

We support your laser cutting requirements wherever you are. From Coventry and the rest of the UK, to Europe and further afield.

Everything you need to know about CNC Laser Cutting

Here is an overview of questions that we are most commonly asked.

Want to learn more?

Laser cutting or profiling is a technology that uses a laser (a highly focussed light beam) to cut materials. It is typically used for industrial manufacturing applications to cut shapes from sheet metal and other materials.

There are very few limitations when it comes to laser cutting. However, when working with thicker plates, the heat generated by the laser may pose challenges. This heat can potentially lead to the burning away of fine details or the unintended closure of small holes.

Laser cutters are incredibly versatile and can cut a wide range of materials, from sheet metals, to wood, paper and plastics, with the right equipment and expertise even glass can be cut with a laser.

Design to delivery, adding value at every stage

Discover how we partner with businesses to add value and bring products to life.