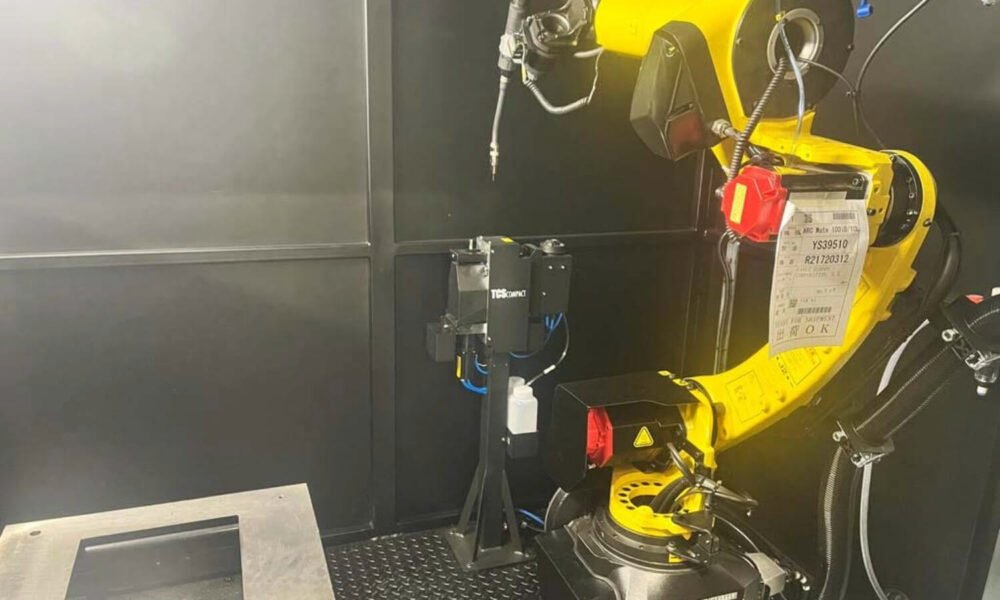

Unifabs, a leading provider of welding and fabrication services, has recently invested in a new robotic arc welding cell. This state-of-the-art system has been sourced and installed by Cyber-Weld Limited, and is now fully operational. The new system comprises a Fanuc 6 axis welding robot (R30ib mate controller), a Kemppi A7 MIG welder and Binzel torch system. This single cell robotic system joins the existing twin cell setup at Unifabs to deliver even more robotic welding capacity.

Increased efficiency and precision

The new robotic arc welding cell is a major investment that will enable Unifabs to increase efficiency and precision in welding processes. The Fanuc AM100id robot is designed to handle a variety of welding tasks with ease, providing consistent and high-quality welds. Its slim curved design, integrated hosepack and utility cables, together with its larger workspace, reach and stroke, allows for a bigger working range. This, combined with a faster working speed, means increased productivity.

The Kemppi 350A A7 MIG welder is a powerful and reliable system that delivers consistent results. While the Binzel torch system is easy to use and maintain, and guarantees a continuously precise and economic welding process. The system also has Kemppi Wise Thin process control, for automated thin sheet welding and brazing. This ensures reliable thin sheet welding and reduces the amount of spatter with all materials.

The combination of these advanced technologies ensures that the new system will significantly enhance our welding capabilities. We will be able to handle more complex welding projects with greater ease, while also delivering superior results in terms of accuracy, precision and repeatability.

Improved safety and quality control

The robotic arc welding cell also includes advanced safety features. These help us to maintain a safe working environment for our employees. The robot is designed to operate in a safe and controlled manner, and to detect any potential hazards.

With the new arc welding cell, Unifabs will be able to improve our quality control processes by reducing the risk of errors and defects. The system also includes Fanuc’s Touch Sensing technology. Touch sensing can be used to teach the robot where the part is located. This can ensure that every weld is consistent and accurately placed. It also allows us to monitor and adjust the welding process when needed.

High quality robotic arc welding and fabrication services

Unifabs’ investment is a testament to our commitment to providing the highest quality welding and fabrication services to our customers. With this state-of-the-art technology, we will be able to increase efficiency and precision in our welding processes, while also maintaining high safety and quality control standards. We look forward to the many benefits that this investment will bring to our business and our customers in the years to come.