Unifabs is excited to announce the installation of a new mezzanine area. This investment has enabled a significant increase in the production capacity for sheet metal assembly services.

Installation of new mezzanine area

Unifabs is a leading manufacturing company specialising in producing high-quality fabricated parts and products for various industries. They required a solution that would unlock further manufacturing capacity, particularly in assembly. Increasing factory floor space in the Finishing building was the ideal solution. With this new addition, Unifabs can continue to deliver its high-quality products and services to its customers.

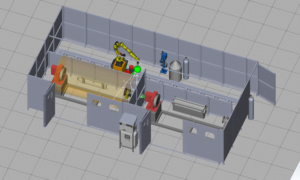

The new industrial mezzanine area is a significant addition to Unifabs’ existing factory floor. The installation of this new area is part of Unifabs’ strategic plan for growth. This will enable them to increase their production capacity and meet the growing demand for sheet metal assembly services.

Installation occurred over approximately three weeks and equates to 2900 sq. ft. of additional manufacturing floor space. Unifabs’ managing director Tom James said “maximising the available vertical space in the Finishing building was the logical choice. This enables us to support more customers with regular, repeating sheet metal assembly contracts and increase productivity and efficiency within this service area”.

Benefits of the new sheet metal assembly mezzanine

The new mezzanine area will bring several benefits to Unifabs and its customers. With the increased floor space, the company will be able to produce more products, leading to faster turnaround times and shorter lead times.

With the increase in dedicated space for sheet metal assembly processes, Unifabs can ensure that its products are of the highest quality. In addition, Unifabs will be able to take on more complex and larger projects.

Benefits in terms of efficiency and safety can also be realised. For example, by providing more space, assembly operatives will be able to move around more freely and complete tasks more quickly. The added space will reduce congestion in the original assembly area thereby making it easier to complete tasks, and maintain a safe working environment. Subsequently, Unifabs will be able to streamline their manufacturing processes and improve productivity

Investing in growth

As Unifabs continues to grow, it remains committed to providing high-quality metal fabrication services to its customers and partners. The installation of the new mezzanine area is just one example of how the company is investing in its future. Ensuring that it remains a leading manufacturer in the industry is a priority. With its experienced staff, state-of-the-art equipment, and commitment to excellence, Unifabs will continue to provide the best possible service for many years to come.

Read more about unifabs’ sheet metal assembly services and get in touch with your manufacturing product requirements today.