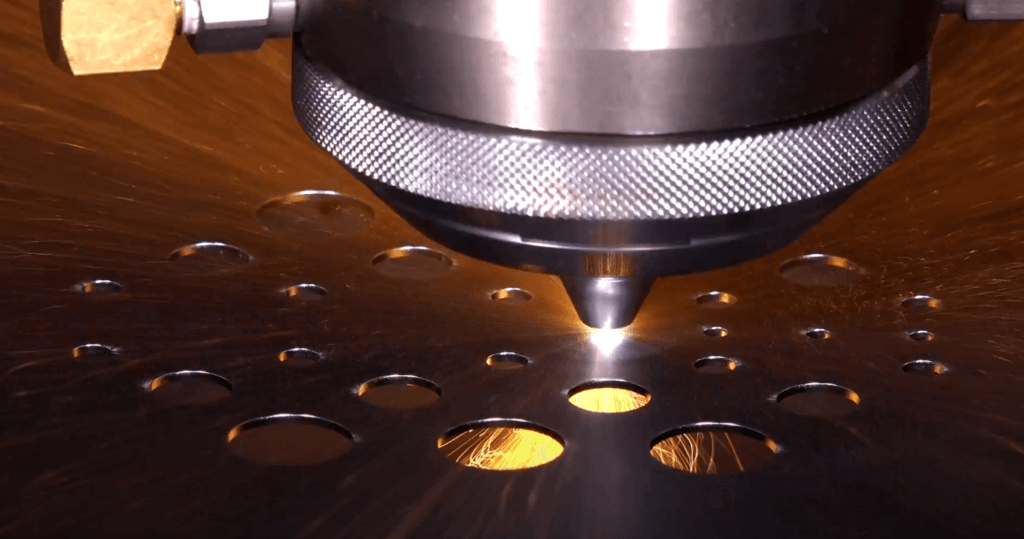

Unifabs has placed significant investments in new equipment in 2021. The latest instalment is a high-specification laser cutting machine from Amada. The REGIUS-3015AJ CNC fibre laser cutting machine is one of the first to be installed in the UK. Here at Unifabs we are excited to share what it can do.

The new investment supports our growth strategy and mission to become a trusted contract manufacturing partner to our customers. Alongside this is the purchase of an AS LUL-3015, for automatic loading and unloading of sheets to the REGIUS and storage of raw material. This will ensure an uninterrupted production run, optimising the laser cutting machinery’s utilisation.

As a company, we pride ourselves on utilising the latest manufacturing technology. Our recent investment in the ground-breaking Amada REGIUS-3015AJ and AS LUL-3015 loading cell will enable us to reduce lead-times and increase capacity, and in turn our customers can deliver their products to market quicker. It’s a great step forward for Unifabs and our partners.

Jason Austin, Managing Director at Unifabs Ltd

Unifabs were already equipped with high-speed fibre laser cutting technology that excelled at medium to high volume runs. With the addition of the REGIUS-3015AJ, our customers will benefit from even more laser cutting capacity. This will mean reduced lead-times but still with the same great quality you’ve come to expect from a Unifabs’ manufactured product.

Bringing the benefits of fibre laser cutting to our customers

This addition to our manufacturing capabilities also provides a multitude of other benefits to our customers; read on to find out how you could benefit.

Ultra-fast laser cutting, reducing lead-times

This new technology from Amada is the fastest in its portfolio; 14% faster than its predecessor. Featuring linear drives on all three main axes, the ultra-fast point-to-point positioning (speed 340m/min), coupled with Amada’s intelligent head control system, achieves incredibly fast point-to-point motion. This in combination with the automatic loading and unloading system optimises the laser’s productivity, allowing for reduced lead-times to you.

Superior accuracy

The full linear drive technology delivers precise accuracy to maximise machine potential. In addition, with most set-up and pre-cut checks done automatically by the laser cutting machine, operator error is vastly reduced.

More reliable laser cutting, equals less down-time

The full 3 axis linear drive technology utilised by the REGIUS-3015AJ consists of less moving parts than traditional mechanical technologies, this means reduced down-time, allowing more throughput and faster delivery to you.

Optimised for quality

In general, laser cutting machines produce high quality cut edges and can manufacture complex designs, with no damage or warping to the materials. However, the REGIUS-3015AJ comes with Variable Beam Control technology which automatically creates a beam shape optimised for each material and thickness. Thus producing high-quality speed-stable cutting to give you an even better finish to your product.

Cost effective

Laser cutting is an economical method of profiling as it does not require any kind of bespoke or modified tooling to be made. It is also able to efficiently nest parts together meaning less waste, reducing cost to the customer.

Fast prototyping

The REGIUS-3015AJ will allow Unifabs to support our customers with prototyping quickly when necessary, without vast disruption to other jobs. The laser profiling centre allows for an off-cut to be placed on the bed at the same time as undertaking another job. It can then automatically interrupt the current job to make the prototype, without having to swap out the original material.

We are excited to see our customers start to benefit from this investment; do contact us for more information on our new laser cutting capacity, or for help and advice on the best methods to manufacture your products.

Although we do offer laser cutting as a stand alone service, our laser facility is the starting point for many jobs utilising our full range of services. These include metal bending (press braking and panel bending), Welding (manual and robotic), Automated Powder Coating and Assembly. Unifabs have the expertise and experience to assist with all of your sheet metal work and fabrication needs. Call us on +44 (0)24 7639 3889 or drop us an email today on sales@unifabs.eu.