We are constantly looking for ways to improve our sheet metal manufacturing services. Ways in which we can make our processes more repeatable, controllable and more efficient. Often that’s achieved through investment in machinery, people and the working environment. But it is just as important to deploy the right systems and software around those physical assets. We have recently made significant investment into Design Automation Software, DriveWorks. This enables us to automate repetitive sheet metal design tasks using a set of rules.

What is DriveWorks?

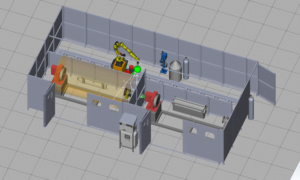

DriveWorks is an immensely powerful design tool. It is particularly useful for our customers that manufacture a consistent style of product that has variations within the range. Our customers can leverage our Design Automation software as part of the production process. With DriveWorks, we are able to produce new designs and all manufacturing data, including 3D models and CNC programmes, all at the click of a button using predefined rules and algorithms.

This means we have significantly reduced the time it takes to get a job production ready. Therefore, it is it out of the design office and into production in a fraction of the time compared to traditional manual design input. In addition, we also eliminate the risk of errors as the rules for design are fixed within the software. All together making our service more efficient and more reliable.

What are the benefits to customers?

Along with the time saved getting a design production ready, another benefit is that it releases otherwised occupied time for additional tasks. In other words it frees our highly skilled Design Team to work on innovation and much higher value tasks for our customers.

We were recently interviewed by our 3D software partner, Solid Solutions. During the interview we discuss our implementation of the software in more detail. You can read the full interview on their website.

If you’d like to know more about how we can add value to your sheet metal manufacturing processes, we’d love to talk to you. Reach out to us on: sales@unifabs.eu or call 02476 393889.

We aren’t just automating design either; read about our latest manufacturing process to be automated: Unifabs Automate Welding And Fabrication With Investment In Robotic Welder