Unifabs has been at the forefront of cutting edge sheet metal fabrication since 2007. Our customers have grown to rely on us for our quality, reliability and the scope of our services. We work with our customers from as early as the initial design stage, through production, powder coating services and assembly, to cover the whole manufacturing process.

Our facility houses industry leading machinery for punching, laser cutting, forming, fabricating, assembling and powder coating services. All designed for processing high volumes of sheet metal parts in an efficient and cost effective manner.

Unifabs is the chosen manufacturing partner in industries that demand the highest levels of quality. Industries such as Retail, Point Of Sale, HVAC, Automotive and Intralogistics. With this in mind, Managing Director, Jason Austin explained, “Any decision to invest in new machinery has to align with our, and our customers demands for quality and efficiency.

Our ambition has always been to offer the complete end-to-end solution to the manufacturing sector. And, to deliver that solution via the best machinery and the best people. Our people are as vital an asset to us as anything else in the business. Our recent award for ‘Excellence in Industry’ speaks to the exceptional levels of service we deliver on a daily basis. It was therefore imperative that the powder coating plant we chose to install also delivers exceptional results”.

Factors to consider in choosing the right system

Whilst the same high standards are required across all parts processed in the Unifabs facility, the nature of them can vary significantly. This meant certain technical challenges had to be overcome when selecting the right powder coating and pre-treatment systems. The systems had to be able to handle:

- High volumes of sheet metal products

- A range of base sheet metal materials

- A wide variety of shapes and sizes

- Multiple colour changes in a shift

- Environmental considerations for energy and powder consumption

- Ease of use for operators

- The highest quality demands and finish requirements

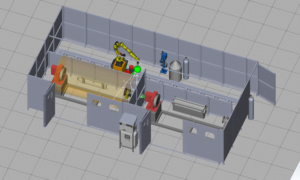

Unifabs powder coating system

The chosen systems consist of a high speed, in-line 3 stage pre-treatment plant, capable of receiving a product envelope of 1400mm x 650mm x 2200mm. The pre-treatment system, provided by paint and powder coat systems experts, TD Finishing Ltd, cleans and prepares raw parts for powder coating at a speed of 1500mm per minute. The technology to apply the powder coat finish is provided by Swiss powder coating experts, Gema. It features their latest innovation, MagicControl 4.0 for Smart Factory Automation as well their most advanced colour change system and OptiFlow injectors, delivering the best finish in the shortest cycle times.

Finishing Department Operations Manager, Steve Penney said of the chosen system, “It’s a fantastic system, it’s a high-speed, multi-metal and highly flexible line that delivers exceptional coating results. With a quick and quality pre-treatment plant, rapid colour changes, highly efficient powder management and pre and post touch up stations, this is the perfect powder coating plant for the volume and variety of sheet metal products we manufacture as well as for the quality we demand of ourselves.” Managing Director, Jason Austin finished by saying, “By adding a state of the art powder coating system to the facility we are now in a position to fulfil our ambition and provide our customers with a truly end-to-end solution.”