Unifabs is pleased to announce another significant investment, this time in welding and fabrication. In collaboration with Cyber-Weld Ltd, we have added a state-of-the-art Fanuc Robotic welding system to our facility. This investment will improve capacity and capability within our welding and fabrication center.

The Unifabs facility houses industry leading machinery for punching, laser cutting, forming, fabricating, assembling and powder coating. The addition of a robotic welding cell will increase our capacity in welding. Also , it will improve the quality and repeatability of the products manufactured in the fabrication centre.

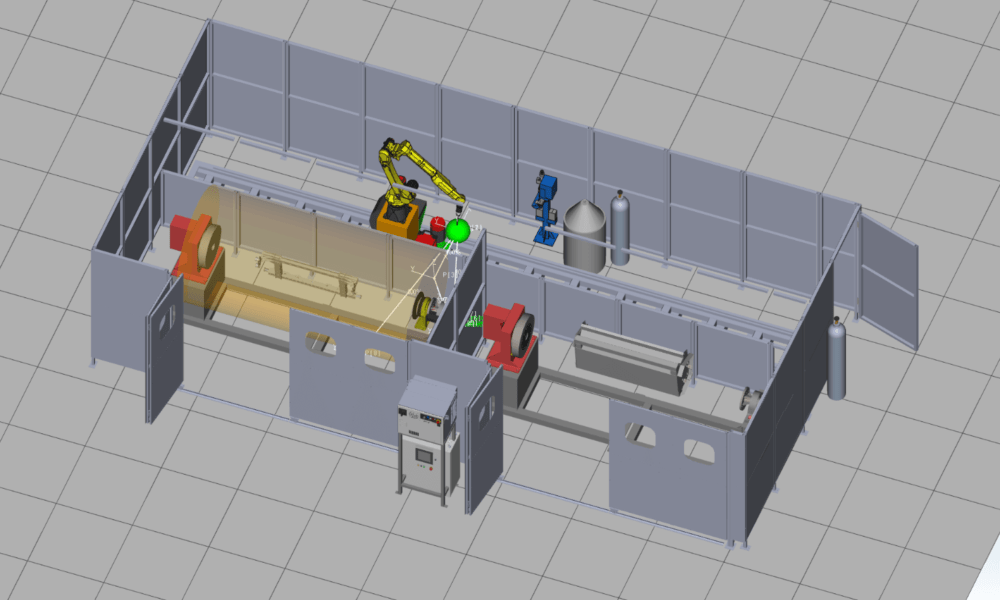

Robotic welding cell system

The system installed is a six-axis Fanuc ARC Mate 110iC, mounted on a 9m track to service two 3m long single axis manipulator stations. The advantage of this cell layout is that the robot can serve either one or both stations. This therefore enables workers to change the tooling or set up the next job while the robot continues welding in the other. Maximising throughput and efficiency in welding.

Jason Austin, Managing Director commented, “Automation is manufacturing’s major opportunity and we’re excited to be able to offer robotic welding to our customers. More and more are asking us to manage the whole manufacturing process for them, including welding, assembly and powder coating. To have the capability to produce more consistent, repeatable welds on the products we manufacture gives us the platform to offer an even better and more reliable service to our customers.”

Thanks to Cyber-Weld for their support throughout. Their team consulted with us expertly and came up with the best design and solution to meet our needs. The attention to detail and response throughout, from automation concept to install and commissioning, was excellent.

Unifabs offer an end to end metalwork solution. With design services in-house and a fully equipped sheet metal fabrication facility, Unifabs is perfectly positioned to be your manufacturing partner. We’re ready to help at every stage of the manufacturing process.

For more information or to discuss your requirements, please contact us on 02476 393889 or sales@unifabs.eu.

You can read more about our manufacturing services and our design capability.