Unifabs are passionate about investing in the next generation of engineers. Through Unifabs apprenticeships we offer a hands-on supportive learning environment within which we help students to develop their knowledge and skills in a variety of manufacturing methods.

In September 2022 we have a number of new apprentices joining us to start Unifabs apprenticeships in Manufacturing Engineering in partnership with North Warwickshire and South Leicestershire College.

Meet Jamie and Eddy, both undertaking Unifabs Apprenticeships

Here two current employees, Jamie and Eddy, answer a few questions about what they’ve learnt so far on their apprenticeships with Unifabs and how they find working here. We also learn a little more about them as individuals just starting out in their careers.

Jamie Hamilton

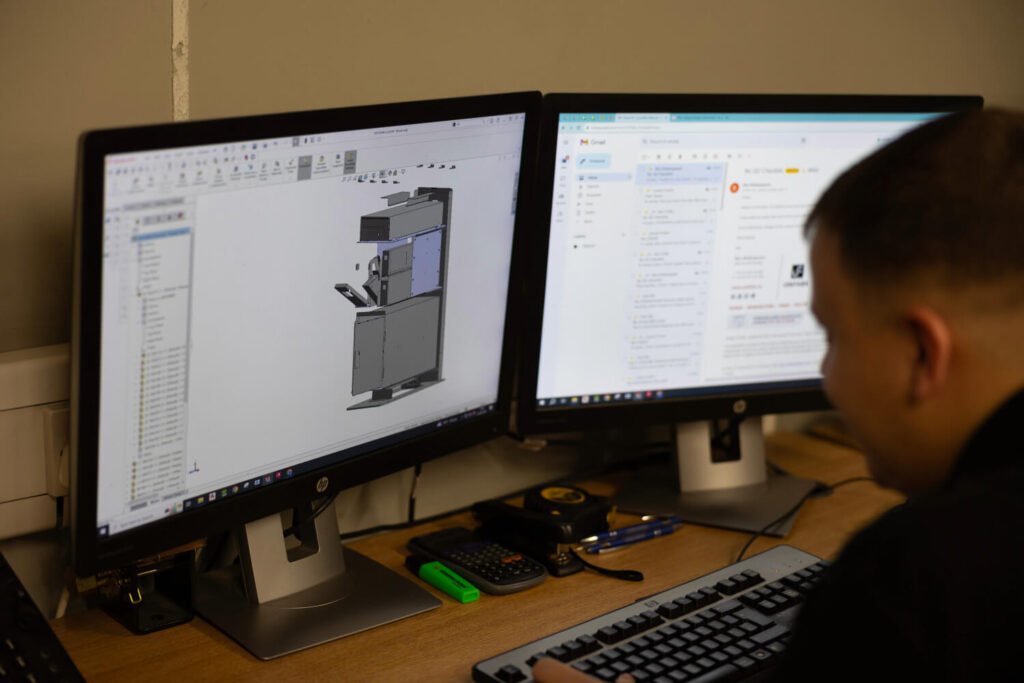

CAD Apprentice

Joined Unifabs February 2022

What are you most looking forward to learning on your Unifabs apprenticeship?

Due to not working in the engineering industry before, I look forward to learning every aspect of engineering. This happens both at college and work as my college course involves more than just CAD. For example, at college I learn other things such as milling, turning and rapid prototyping. I look forward to starting to work on bigger projects in the CAD office as I become more competent and skilled at my role.

What is a typical day for a Unifabs Design apprentice?

Apart from going to college on a Thursday, I work a full working week here at Unifabs. I come in at 7:30am and a typical day for me at the moment involves working on sample parts for customers. We have a R&D prototype area and currently I am putting a lot of work through this area, working on different projects day to day. This involves me creating models/drawings, asking for material/components to be ordered and getting things cut in the CNC factory.

How would you describe the kind of people that work at Unifabs?

All the employees at Unifabs are very skilled and knowledgeable at their role. Everyone I have met so far have been very polite and helpful when needed. In the CAD office the lads are very open to teach me new things every day and have been very helpful from day one as SolidWorks is brand new to me. The managers here are very good at listening to all the employees and they also find time for everyone when it’s needed.

Describe your first impression of Unifabs in 3 words?

Professional, organised and impressive

Just for fun…

With an apprenticeship you earn while you learn. What did you spend your first wages on and what would you most like to splash out on?

I spent my first wage slip on repairing my car unfortunately due to a damaged suspension. It’s very rare that I splash out but recently I bought myself a new car and booked a holiday with my girlfriend. In the future my only big purchases will be holidays and then eventually a house. I am pretty sensible with my money and tight!

What was your favourite subject at school?

In school my favourite subject was PE. PE had many areas to learn such as nutrition, the history of sport, the psychological side of sport and how the body works. This interested me as growing up I thought PE was all about playing sport and eating well. It was also one of my strongest subjects in school alongside biology which overlapped in some areas. This also made me enjoy PE more as a whole.

Eddy Moore

Manufacturing Engineering Apprentice

Joined Unifabs March 2022

What are you most looking forward to learning in your manufacturing apprenticeship?

I’m looking forward to developing new skills, learning how to use new equipment, and in time becoming a skilled and dependable employee.

You have been at Unifabs for almost 4 months now, what have you learnt so far?

During the time I’ve been at Unifabs I have gained a lot of knowledge of the press brake including how it works, how to operate it and understanding different tools. I’ve also started to develop welding/fabrication skills and worked on a lot of sample products.

What are your future ambitions upon completion of your Unifabs apprenticeship?

My ambition is to be employed full time upon completion of my apprenticeship. Ultimately, I want to become a qualified engineer with a variety of skills that can be carried out to a high level.

How would you describe the kind of people that work at Unifabs?

Respectful, hardworking and knowledgeable

Just for fun…

What was your favourite subject at school?

History, I particularly enjoyed learning about modern history.

What do you enjoy doing in your spare time?

Socialising with friends, watching football, going to the gym, and DJing.

If you are interested in Unifabs apprenticeships, get in touch with us, you could be a future Unifabs Apprentice too.